Forging Designs Create Superior Strength & Durability

A part’s strength is defined by how much stress the part can take before it begins to fail or break. Excavators, backhoes, tractors, combines, conveyors, trucks… Heavy equipment components must have the strength to endure the most punishing environments. This is why there is more to a forged gear than the initial price tag.

A cheaper part does not always equal cost savings, especially if the component does not perform consistently during machining and equipment performance. Fortunately, there are cost-effective, turnkey forging techniques that can dramatically increase strength for more durability and reliability.

Assessing Metallurgical Properties That Add Value

Metallurgy matters when it comes to how well an axle flange or drive gear will hold up for workhorse machinery like an off-road pickup truck or an excavator. An experienced engineer can design the process to ensure the grain flows, microstructures, and final mechanical properties in steel forgings create consistently stronger parts for more reliable, consistent performance.

These metallurgical factors can:

- Increase strength and toughness critical for components such as axle side gears, spiders, and differential case parts.

- Deliver the mechanical strength-to-weight ratio for performance durability in heavy equipment use.

- Eliminate weaknesses associated with other manufacturing methods, which make parts unreliable and prone to failure, such as porosity in casted parts or undesirable grain flow in machined-from-bar stock parts.

- Reduce machining time by minimizing excess stock through forging design.

- Ensure consistent machining characteristics through control or modification of steel microstructures prior to machining.

Improving Mechanical Properties With Heating & Cooling

Multiple types of heat treating techniques exist that are designed to enhance the performance of steel, whether the goal is increasing strength, toughness, or machinability. These techniques can further enhance steel’s metallurgical properties in ways essential to heavy equipment components, such as drive and bevel gears.

Heat treating processes applied to raw forgings include:

- Sub-Critical Annealing: Forgings are heated to temperatures in the 1100°F - 1300°F range and slow or air cooled. This process is used to reduce material hardness or relieve residual stresses.

- Full Annealing/Iso-Thermal Annealing: Forgings are heated to temperatures generally in the range of 1500°F - 1750°F and then allowed to cool gradually in a controlled fashion. This process generates a softened part with consistent microstructure and is often used to improve machining characteristics on steels with higher hardenability.

- Normalizing: Forgings are heated to temperatures generally in the range of 1500°F - 1750°F and then air cooled. This process generates a fine-grained structure which improves machinability and promotes dimensional stability and consistency of response in subsequent heat treating processes. The grain refinement and consistency of properties produced makes this process suitable to produce the final properties required for certain applications.

- Hardening and Tempering: Forgings are heated to temperatures generally in the range of 1500°F - 1650°F and quenched in a liquid medium, such as oil, polymer solution, or water. After quenching, the forgings are re-heated to a temperature below 1300° and air cooled. The quenching causes the steel to harden and increase in tensile strength. However, the steel is then too hard and brittle to be usable. The reheating (tempering) softens the steel to the desired hardness and strength level, increasing ductility and toughness in the process. Hardening and Tempering is usually used to produce the in-service properties required of the forging.

In some cases, heat treating steps can be eliminated utilizing conveyor/controlled cooling. After hot forgings come off the press and are trimmed, they are cooled in still or accelerated air on conveyors to a specified temperature. This process is ideal for parts made from certain micro-alloy steels, or where the primary goal of heat treating would be to generate consistent machining characteristics.

A full-service forger can meet specific customer requirements for mechanical properties by selecting the appropriate heat treatment for each part. This means the forger can accommodate a wide variety of customer requirements.

Predictive Testing to Assess Forging Performance

Expected part performance should be assessed prior to part installation, or even machining. A variety of techniques exist to predict and assure product capability.

These testing techniques include:

- Forging Simulation Software: Ensures appropriate material/grain flow of the part before the first die is made or the first part is forged.

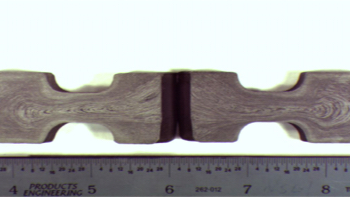

- Macro Etching: Shows the actual grain flow of forgings to verify conformance to intended design.

- Hardness Testing: Allows rapid “on the floor” testing of parts to ensure appropriate steel hardness, and can be used to estimate tensile strength

- Tensile Testing: Produces data regarding the strength and ductility of the forging.

- Charpy impact testing: Provides data on the toughness of the forging. Testing is often performed at refrigerated temperatures to ensure suitability of the product, even in sub-zero applications.

- Microscopy: Used to determine microstructure and grain size of product to further ensure product performance.

These methods are used to ensure parts consistently meet performance criteria batch after batch, whether those criteria are simply consistent machining characteristics or in-service durability.

Presrite: Superior Performance Forgings to Save Time & Money

Presrite can design forgings that can reduce machining cycle times by minimizing excess material stock and maximizing machining consistency. Presrite forgings also maximize product strength to weight ratios by having superior grain flow and inherent strength than other manufacturing methods. Presrite forging technology, combined with appropriate heat treating methods, produces products that achieve superior performance, while saving time and money.

Our state-of-the-art Technical Center, along with our forging locations, our Metallurgical Lab, and vetted sub-supplier partners, can design and produce forgings to our customers’ high quality requirements.

Consistent metallurgical properties and repeatable precision are critical ingredients to producing parts that reduce machining cycle time, wear and tear, and expensive downtime.

Presrite’s professionals can work with your staff to find engineering solutions that meet your industry’s machining needs and performance requirements, all while saving you time and money.

Contact us today to learn how Presrite’s forging professionals can work with you to save you time and money. Or, read our white paper to learn more about our turnkey forging solutions.